Single table fiber laser cutting machine

Classification:

Product Details

Product advantages

The company independently designed desktop CNC machine tool system, the use of high-strength overall welding body, after heat treatment aging treatment, large CNC machine tool precision processing.

The machine tool has good rigidity and stability, and runs with rack and pinion drive.

High precision and fast speed.

Oxygen and nitrogen can be used as auxiliary gas for perfect cutting.

Using advanced fiber laser, stable performance.

The laser has excellent beam quality, high photoelectric conversion rate, maintenance-free, stable and reliable, and has the characteristics of low operating cost and small size, so that the cutting line is finer, the work efficiency is higher, and the processing quality is better.

The use of advanced cutting head control technology, cutting head automatic fault alarm protection display function, the use of more assured, more convenient adjustment, more perfect cutting.

Equipped with high-precision, high-response drive, suitable for fast precision cutting.

Equipped with a centralized automatic refueling system, so that all parts are fully lubricated and the service life is improved.

Technical parameters

| laser medium | semiconductor pumped continuous doped mirror fiber |

| Maximum cutting range (length × width) | 3x1.5m / 4x2m / 6x2m / 6x2.5m / 8x2.5m / 12x2.5m |

| Maximum speed | 80m/mi n |

| Cooling mode | Water cooling |

| laser wavelength | 1. 07um |

| Laser generator power | 1500-12000 w |

| Minimum line width | ≤ 0.12mm |

| Cutting material thickness | 0.5-30mm (depending on laser power) |

| Driving mode | Imported servo motor |

| power supply demand | 380V/50Hz |

| Continuous working time | 24 hours |

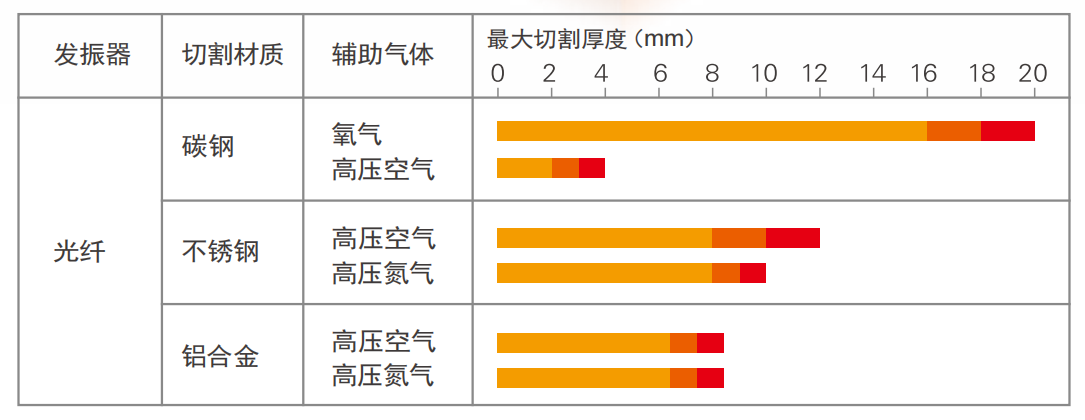

The processing capacity table takes the mainstream high-end 3000W laser on the market as an example.

* The data values in the above processing capacity table reflect the original capacity under certain conditions, and the acceptance conditions refer to the specification.

* Although the processed material belongs to the same specification, there are sometimes differences in processing performance and quality due to different surface conditions and ingredients.

* Due to the different processing shapes, sometimes there are differences in processing performance and quality.

Keywords: large laser fine plasma gantry plasma 3D robot

Previous:

The next one:

Online consultation