3D laser cutting robot

Classification:

Holes and frames of various shapes are formed at one time, saving the development cost of full-order die or blanking die.

Due to the good quality of the cut, there is no need to polish after cutting, which can shorten the process and save labor costs.

Improve product quality and grade, increase product added value.

Product Details

Product advantages

- Holes and frames of various shapes are formed at one time, saving the development cost of full-order die or blanking die.

- Due to the good quality of the cut, there is no need to polish after cutting, which can shorten the process and save labor costs.

- Improve product quality and grade, increase product added value.

- Save the time to develop the mold, convenient and more flexible to replace the product, conducive to the early listing of products, to seize the market.

- Industrial control concept, modular design, high intelligence and practical operation combined with high protection integration technology.

- For your personalized full set of automotive sheet metal panels and chassis parts cutting solutions.

- The application of professional off-line programming software, through the numerical control directly generate cutting trajectory, abandon the complex manual teaching, more suitable for small batch.

- Multi-batch maintenance market, new product trial production and non-standard customization and other personalized cutting needs.

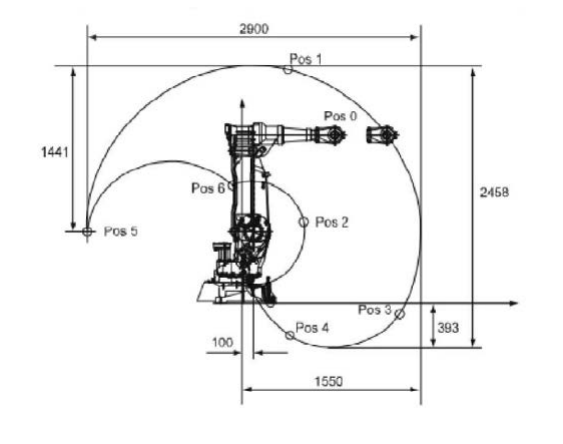

Rotatable angle of each axis of the robot

First axis: 180 °-180 °

Second axis: 110 °-100 °

Third axis: 65 °-60 °

Fourth axis: 200 °-200 °

Fifth axis: 120 °-120 °

Sixth axis: 400 °-400 °

(Take ABB robot hand as an example)

The robot can reach the processing range

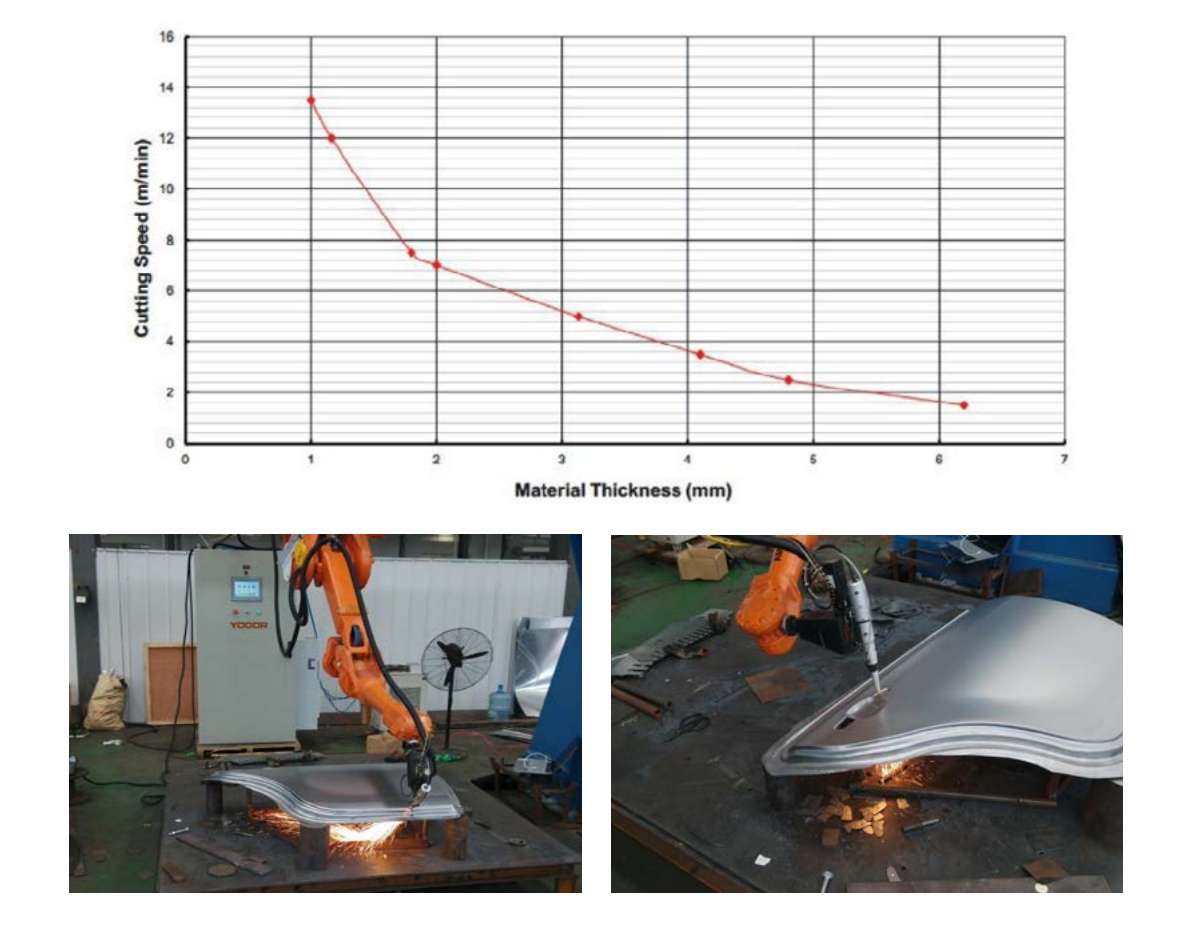

Cutting curve of speed corresponding to steel plate thickness when using 500W fiber laser

Keywords: large laser fine plasma gantry plasma 3D robot

Previous:

The next one:

Online consultation