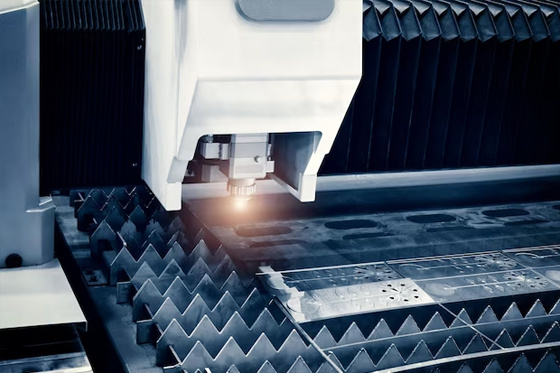

Metal CNC plasma cutting machine cutting saw teeth specific reasons

In the use of CNC plasma cutting machine, sometimes encounter some problems, such as when we CNC plasma cutting machine cutting products will appear when the cutting section of the problem, what is the cause of this situation.

1. The guide rails are not parallel.

The installation of the two guide rails in the Y-axis direction is not parallel. When the CNC plasma cutting machine is running, it will be stuck. When cutting, it will also cause the cutting section to have serrations.

2. Gear, gear seat, etc.

If the edge of the gear seat is close to the seat, causing slippage, etc., the CNC plasma cutting machine equipment also causes this situation to occur.

3. Machine parallelism.

If the parallelism of the CNC plasma cutting machine is not installed properly, and the machine is running, it will not be stable, then it will also produce jitter during the operation, and the cut product will also occur in the serrations.

4. Slider is worn.

There is wear in the slider or a lot of things are stuffed in the beads of the slider, and the CNC plasma cutting machine shakes when running on the guide rail. So when cutting materials, there will be a lot of serrations.

5. The electrode/nozzle is not locked.

Sometimes, if the electrode/nozzle is not locked, the electrode/nozzle will also vibrate when the machine is running, and the arc will also vibrate when the machine is cutting, so the cut product will not work well, and there will be sawteeth. occur.

6. Vibration.

If the CNC plasma cutting machine vibrates, then the product it cuts will be serrated. It is divided into two reasons. One is the external situation of the machine, such as the machine in the cutting process, such as water tank, the exhaust fan will not be too close, if too close, leaning against the machine tool, it will vibrate the machine tool when it is running, the machine will vibrate when cutting materials, which will affect the cutting edge effect.

If there are serrations during cutting of the numerical control plasma cutting machine, you can press and hold the plasma cutting head by hand to prevent it from shaking when it is running. if you press and hold it by hand, it must be a slider problem. If there is still a problem, then you have to check the belt and gear. If there is a new machine, it must be that it was not installed properly when it was installed, or the control drive of the CNC plasma cutting machine and the servo motor pulse are not paired.

There are several reasons for the serrated cutting section of the CNC plasma cutting machine. I hope it will be helpful to everyone. If you have any other questions you don't understand in practice, please feel free to contact us!

Keywords: large laser fine plasma gantry plasma 3D robot

RELATED INFORMATION

How to effectively avoid smoke and dust by CNC plasma cutting machine

2024-01-26

Metal CNC plasma cutting machine cutting saw teeth specific reasons

2024-01-26

What is the difference between CNC plasma cutting machine and laser cutting machine

2024-01-26