How to effectively avoid smoke and dust by CNC plasma cutting machine

In the process of operating the CNC plasma cutting machine, noise, smoke, arc and metal vapor will occur, which will pollute the environment. Now most CNC cutting machine manufacturers participate in the water storage tank under the operation table to avoid smoke and dust and fly randomly. The situation is particularly serious when large current cutting may cut non-ferrous metals.

Now the editor will tell you that there are several different equipment and skills that can be used to reduce this level of pollution:

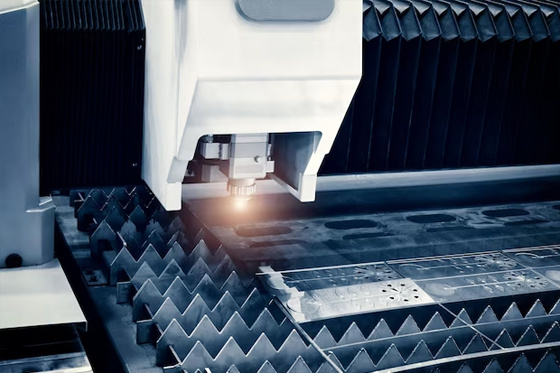

There must be a water storage tank for cutting on the water surface. The top of the water storage tank is a working platform for placing workpieces. The working platform consists of a plurality of orderly steeple-shaped steel members, and then the cut workpieces are supported on a horizontal plane by these steeple-shaped steel members. During the operation of the cutting gun, the vicinity of the plasma arc is enveloped by a water curtain. In order to stick to the successive water curtains, a reincarnation pump is required to pump the water out of the storage tank before driving it into the cutting gun. When the water is ejected from the cutting gun, it forms a water curtain that envelops the plasma arc. This water curtain greatly controls the damage to the environment caused by pollutants such as noise, smoke, arc light and metal vapor that occur during the cutting process. The water flow rate required by this method is 55 ~ 75L/min.

Underwater cutting involves placing the workpiece about 75mm below the surface of the water. The table on which the workpiece is placed consists of a spiral element made of steel. Spiral steel members are selected so that the shear deck has sufficient capacity to contain debris and slag. When the chopper is injected into water, the water near the end surface of the chopper nozzle is blown out by constant-current compressed air, and then the plasma arc is ignited for cutting. When cutting underwater, the workpiece should be kept at the depth of the water. A water level control system should be prepared, and water pumps and water storage tanks should be added to maintain the water level through irrigation and drainage. Generally speaking, an exhaust system should be installed around the cutting table of a manual CNC plasma cutting machine or a CNC plasma cutting machine to take the exhaust gas away from the workshop. However, the exhaust gas continues to pollute the environment. If the pollution exceeds the national allowable standard, it is necessary to increase the smoke transition equipment.

Exhaust treatment is generally only for the cutting surface, part of the air flow is specially managed to prevent part of the workplace from being polluted by harmful substances and maintain a good air environment. Generally speaking, the exhaust device of some CNC plasma cutting machines consists of four parts: the air collecting hood, the air duct, the purification system, and the fan. According to the different ways of gas collection, local exhaust can be divided into fixed local exhaust system and mobile local exhaust system.

Keywords: large laser fine plasma gantry plasma 3D robot

RELATED INFORMATION

How to effectively avoid smoke and dust by CNC plasma cutting machine

2024-01-26

Metal CNC plasma cutting machine cutting saw teeth specific reasons

2024-01-26

What is the difference between CNC plasma cutting machine and laser cutting machine

2024-01-26