What is the difference between CNC plasma cutting machine and laser cutting machine

In fact, many friends are not very clear laser cutting machine and CNC plasma cutting machine to cut out the effect of what is the difference, like our daily life of sheet metal processing in the end need laser cutting machine or CNC plasma cutting machine?

The following is to explain the difference between laser cutting machine and CNC plasma cutting machine, and how to choose in different environments.

First of all, I would like to tell you the working principle of these two types of cutting machines.

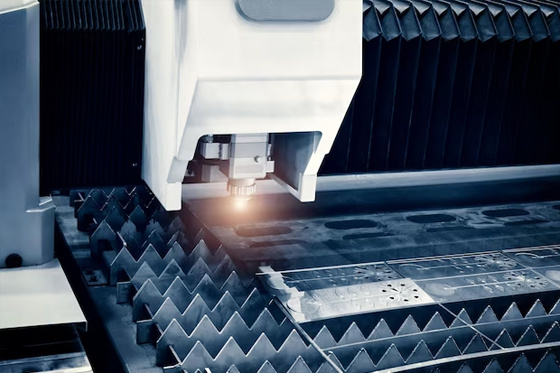

1. The working principle of laser cutting machine

The laser cutting machine focuses the laser emitted by the laser into a high power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point. At the same time, a high-pressure gas coaxial with the beam blows away the molten or vaporized metal. So as to achieve the purpose of cutting.

2. The working principle of CNC plasma cutting machine

CNC plasma cutting machine to increase to a certain temperature. It transfers the arc power to the workpiece. The high temperature causes the workpiece to melt and be blown off, forming the working state of plasma arc cutting. The metal is then melted using a plasma arc as a heat source. Cutting is an arc, so there is often a certain arc when cutting failure. Therefore, when the cross-section we need is a right angle, the CNC plasma cutting machine is no longer applicable.

Secondly, I 'd like to tell you about the differences in cutting materials, cost and precision of the two cutting machines.

1. Different cutting quality

In terms of cutting accuracy, plasma can reach within 1 m m, and laser can reach within 0.2 m m. Therefore, the accuracy of the laser cutting machine is higher.

The laser cutting machine can realize non-contact cutting with the surface of the workpiece, with small cutting gap, high precision, small heat-affected zone, and smooth cutting end surface without burrs. The cutting gap of the CNC plasma cutting machine is large, the cutting end surface is rough and not smooth, and the cutting accuracy is low.

2. Different cutting materials

Laser cutting machine is suitable for cutting a wide range of materials: metal, non-metal, ceramic, glass, etc.

CNC plasma cutting machine is suitable for cutting all kinds of metal materials, mainly thick plate cutting.

3. The cost is different

In terms of the cost of consumables, the cost of consumables for CNC plasma cutting machines is very high. For example, the entire cutting torch (nozzle, swirl ring, electrode, etc.) needs to be replaced within a few hours, and the CNC plasma cutting machine consumes a lot of power.

The cost of consumables for laser cutting machines is very low, there are few wearing parts, and almost no maintenance is required.

Wuhan Huayucheng CNC is a manufacturer focusing on CNC equipment and laser equipment. After 13 years of development, its CNC equipment and laser products have become more mature. It has always implemented the price as the standard to measure value and strived for low price, high quality and high service concept.

Keywords: large laser fine plasma gantry plasma 3D robot

RELATED INFORMATION

How to effectively avoid smoke and dust by CNC plasma cutting machine

2024-01-26

Metal CNC plasma cutting machine cutting saw teeth specific reasons

2024-01-26

What is the difference between CNC plasma cutting machine and laser cutting machine

2024-01-26