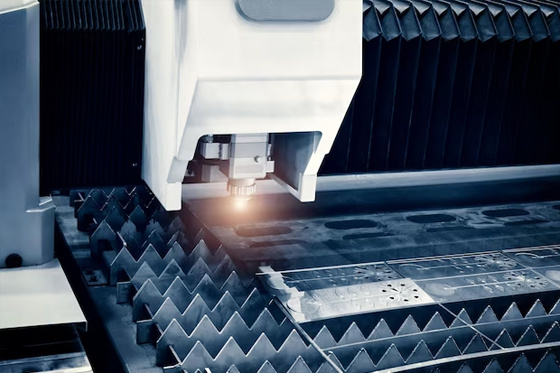

Gantry CNC plasma cutting machine efficient operation points

As an important application category of thermal cutting, the gantry CNC plasma cutting machine has good performance in terms of cutting efficiency and cutting accuracy. However, judging from the current operating conditions of most domestic production enterprises, there are very few enterprises that can truly achieve high-quality and efficient operations. So what is the level of operation of the gantry CNC plasma cutting machine, mainly reflected in the following aspects:

The height and stability of the cutting nozzle: The parts cut by the gantry CNC cutting machine can be directly welded and used without mechanical processing. However, the gantry CNC plasma cutting machine uses plasma arc cutting, which is compared to oxygen cutting. There are still some defects, which are mainly reflected in the large inclination of the cutting surface and the smoothness is not as good as that of oxygen cutting. The main criteria for evaluating the quality of CNC plasma cutting are: the inclination of the cutting surface, the cutting depth of the cutting seam, the amount of slag, etc.

Matching of cutting speed and working air pressure: Gantry CNC plasma cutting machine is an advanced mechatronics metal plate cutting equipment. It has been widely used in shipbuilding, machinery manufacturing and other industries. There are many factors that affect the cutting quality of the gantry CNC plasma cutting machine. In addition to the design parameters of the cutting machine, it is also related to operation control and cutting technology.

For a high-quality cutting surface, the inclination should be below 30, the cutting depth should be below 0.15mm, and the slag is small and easy to remove. When the height of the cutting nozzle from the steel plate is controlled by the arc pressure regulator, the dynamic positioning accuracy can reach/-0.013 liters, so the height of the cutting nozzle and the steel plate can be guaranteed to remain unchanged, so the inclination of the cutting surface is small and uniform, and the finish is good. When manually adjusting the height of the cutting nozzle from the steel plate, the steel plate to be cut should be leveled as much as possible to reduce the number of adjustments to the torch and ensure the stability of the torch cutting process.

If manual adjustment is used, the height of the cutting nozzle from the steel plate is controlled at 6-8mm, and a series of cutting tests can prove that the cutting quality has been significantly improved. In addition, in order to improve the cutting quality, we carried out a comprehensive cutting test, analyzed and sorted out the test data, and obtained some great working parameters of the gantry CNC plasma cutting machine. Now introduced as follows: CNC plasma cutting machine can cut a variety of complex shapes of the workpiece, with cutting speed, high efficiency, cutting surface quality, cutting size accuracy, small thermal deformation of the workpiece and so on.

Keywords: large laser fine plasma gantry plasma 3D robot

RELATED INFORMATION

How to effectively avoid smoke and dust by CNC plasma cutting machine

2024-01-26

Metal CNC plasma cutting machine cutting saw teeth specific reasons

2024-01-26

What is the difference between CNC plasma cutting machine and laser cutting machine

2024-01-26